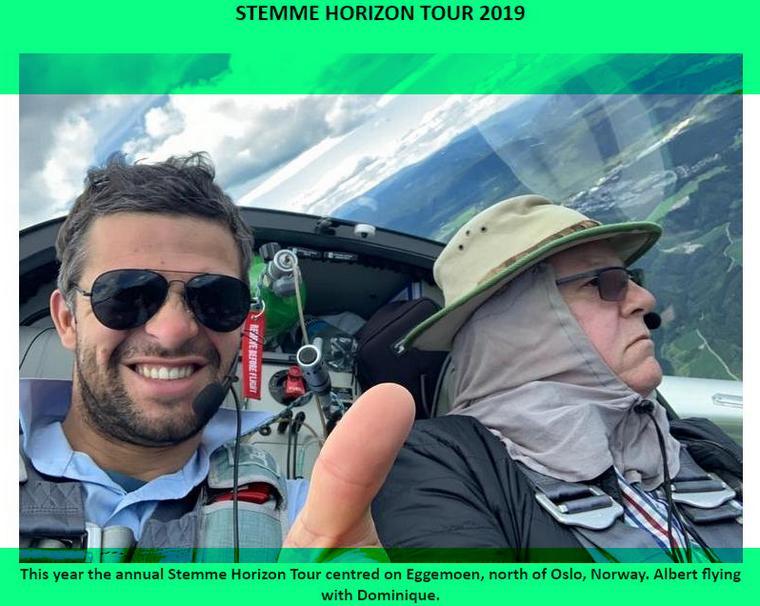

MIDWEEK UPDATE 23 OCTOBER 2019         30 to 2 Nov: SAPFA Rally Championships - Stellenbosch airfield. Contact Frank Eckard cell: 083 269 1516 e-mail: frank.eckard@mweb.co.za   2: SAPFA Rally Championships - Stellenbosch airfield. Contact Frank Eckard cell: 083 269 1516 e-mail: frank.eckard@mweb.co.za 2: Volksrus Breakfast Run. For more information contact Donald Hicks Donald@aqpm.co.za 2: Fete, Parade and Veterans Military Fair to be hosted by Moth Ex-Servicemen's Cottage Association. Moth Ex-Servicemen's Cottage Association, along with MOTH Shellhole, Dickie Fritz, Edenvale. 7-8: SAAMA Safari Cup. Henley Model Airfield. 8-10: EAA Sun n Fun Brits Airfield. For more information contact Marie Reddy 083 259 7691 9: EAA Sun & Fun Adventure Rally - Contact Rob Jonkers e-mail: rob@aerosud.co.za cell: 082 804 7032 15: Wings Park Fly-in. For more information contact Donald Hicks Donald@aqpm.co.za 16: Aero Club of South Africa annual awards. For more information contact AeCSA office 011 082 1100 E-mail: office@aeroclub.org.za 16-17: Wavecrest Fly-in. For more information contact Donald Hicks Donald@aqpm.co.za 22: World Canopy Piloting Championships Wonderboom South Africa. 23: SAPFA Springs Speed Rally - Springs Airfield. Contact Jonty Esser cell: 082 855 9435 e-mail: jonty@promptroofing.co.za 30: The Elders Flight, Rand Airport. SMS Felix Gosher on 066 485 0407 30 to 1 December: SAC Ace of Base Vereeniging Airfield. Contact Annie Boon e-mail: chunge@mweb.co.za   18 - 19: SAC Gauteng Regionals Annie Boon chunge@mweb.co.za 25: Rand Airport Challenge Rally - Rand Airport Contact Frank Eckard e-mail: frank.eckard@mweb.co.za cell: 083 269 1516 25: SAPFA AGM - Time: 2 PM Rand Airport Contact Rob Jonkers e-mail: rob@aerosud.co.za cell: 082 804 7032    The high-speed tests will see the Bloodhound LSR car blasting along the Hakskeenpan desert racetrack for the very first time, providing a spectacular showcase of British engineering to a global audience. The Bloodhound team's primary objective is to engage and inspire people of all ages through the most extreme application of science, technology, engineering and mathematics. The most powerful straight-line car ever was transported on the same pneumatic tyres as the car ran on in Newquay, and, as well as allowing the car to be manoeuvred on tarmac, they also increase the effective damping of the car, further protecting the car and systems from any shocks during its travels. Unable to stand up to the extreme stresses of high-speed driving, these will be swapped out for precision machined solid aluminium wheels ahead of launch.  Once these narrower wheels, made specifically for desert testing, are fitted, engineers will be able to re-attach sections of carbon fibre composite bodywork to the front of the car, along with the nose section, which is vital for effective aerodynamics. The tail fin will also be fitted, completing the chassis and making the car ready for action. The 25-strong team who flew out with the car joined an advance party who have been working tirelessly beneath the South African sun to set up the 50 x 50 m Desert Technical Camp on the edge of the Hakskeenpan desert. As well as the Bloodhound car itself, it houses a temporary workshop, complete with the precision tools needed to fine tune performance and maintain the car, including a lathe, milling machine and welding equipment. The Bloodhound LSR car was unveiled in all its fully assembled glory on the 21st October, before it begins the high-speed test programme, during which it will build speed gradually in 50 mph increments over a month. The culmination of the four to five weeks will see the car hitting mind-blowing speeds of 500+ mph (800+ km/h). Bloodhound LSR driver and current World Land Speed Record holder Andy Green said: "After years of work to prepare the car, and following almost a decade of preparation of our desert track by the Northern Cape Government, we're delighted to finally be here. The next few weeks will allow us to test the car and train the team, ready for our assault on the Outright World Land Speed Record next year." World's New Straight-Line Racing Track The 10-mile (16 km) desert racetrack has been prepared by 317 members of the local Mier community, funded by the Northern Cape Government. They have moved a staggering 16,500 tonnes of rock from 22 million square metres of dry lakebed - the largest area of land ever cleared by hand for a motorsport event, and testament to the partnership forged between the Bloodhound team, the local community and the Northern Cape Government.  Bloodhound CEO Ian Warhurst explained: "The section of the track we'll use is 16 km (10 miles) by 250 m, with large safety areas on both sides. This allows us to lay out up to 25 individual tracks side by side, if we need them. This is important as we can't run over the same piece of ground twice because the car will break up the baked mud surface as it passes. We need multiple tracks so we can build speed slowly and safely - going up in 50 mph (80 km/h) steps, comparing real-world results with theoretical data - and Hakskeenpan is the perfect place to do this. "The surface is hard, too, which means we've been able to design slightly narrower wheels that reduce aerodynamic drag. The desert surface also has a slight degree of 'give', which will work with the suspension to give a smoother ride, reducing vibration inside the car." The Bloodhound Land Speed Record programme is a UK-based global endeavour exploiting the cutting-edge of digital technologies to set a new World Land Speed Record. By sharing this adventure with a global audience, Bloodhound will help inspire the next generation about science, technology, engineering and mathematics, and will be a supersonic testbed for showcasing emergent digital technologies. Key Facts The Bloodhound LSR car is a combination of fast jet, F1 car and spaceship. The project is followed in over 220 countries and territories. At full design speed (1,050 mph), Bloodhound LSR could cover a mile (1.6 km) in 3.6 seconds - that's 4.5 football pitches laid end to end, per second, or 150 m in the blink of an eye. The World Land Speed Record of 763.035 mph (1,227.9 km/h) is held by Thrust SSC. The record was set in 1997 by a UK team led by Richard Noble and driven by Bloodhound's Andy Green. 1,000 mph The project is now split into two phases. Phase one's target is to break the world land speed record (currently 763.035 mph / 1,227.9 km/h). This is necessary to understand how the car behaves as it enters the transonic stage initially and then supersonic speed levels. Upon the successful completion of phase one, the team will review the data and technical challenges before embarking on phase two, and the challenge of safely reaching 1,000 mph. Engine for high speed testing The high-speed testing will be conducted using the car's Rolls-Royce EJ200 jet engine, normally found in a Eurofighter Typhoon. These engines produce a peak thrust of 20,000 lbs (90 kilonewtons), equivalent to 54,000 thrust hp, or the combined output of 360 family cars. Wheels The solid aluminium wheels have been specially designed for the desert surface. Measuring 900 mm in diameter and weighing 90 kg each, they are designed to spin at up to 10,200 rpm (revolutions per minute) - more than four times faster than wheels on a Formula 1 car at top speed. The result of 30 years of research and design, they were created by an international consortium and forged from one of the highest aircraft grade aluminium alloys in the world: 7037.  The wheels have a V-shaped keel which digs into the alkali playa (baked mud) surface by 15 mm when the car is stationary. As speeds increase, the wheels will rise up out of the mud surface and plane in much the same way as a speedboat rides up on the surface of the water. At 500 mph (804 km/h) and above, just a few millimetres of metal will be in contact with the desert surface, and the giant aluminium discs will act more like rudders than the wheels on a conventional car.  After several years of visiting alpine regions in the south of Europe this year's Horizons Tour took us to the far north. Norway, known for its pure nature in combination with extraordinary local food, drinks and long days has kept its promise and treated the group of Stemme owners and enthusiasts well. With a total number of 22 participants from over 8 countries (including South Africa) and 7 Stemme aircraft our major aim was to discover the beautiful landscape from above. In 1984, Dr Reiner Stemme founded the company Stemme GmbH & Co. KG in the Berlin district of Wedding in order to realize his vision of a unique aircraft: the aim was to combine the properties of powerful motorized propulsion with first-class gliding characteristics. By 1986, the prototype of the S10 embarked on its maiden flight and one year later was unveiled to the public at the AERO trade show in Friedrichshafen. In 1990, type certification was finally granted and the first series-production version of the high-performance motor glider was ready for delivery. In the same year, Stemme changed its corporate form to a joint-stock company. The S6 had its maiden flight in November 2006 and received type approval from EASA two years later. In April 2015 Stemme presented the Twin Voyager S12 at the Aero exhibition in Friedrichshafen. Bart Slager was announced as the new Chief Executive Officer (CEO) of the company as of 28 August 2019. His focus will be on further strengthening both the Remos and Stemme brands as well as the transition and growth of Stemme.   Succeeding the TBM 930 on the production line, the $4.13 million TBM 940 is equipped with Garmin G3000 avionics, an intuitive single smart engine gauge, and a Daher/Garmin autothrottle, the first single-engine turboprop weighing less than 12,500 introduced with that feature on the production line. Additionally, the TBM 940 has new functionality through its Garmin GWX 70 radar, including turbulence detection, and along with its sibling TBM 910, comes with a new automatic icing-detection system. The TBM 940's cabin also received a refresh with redesigned seats, additional thermal insulation in the cabin sidewalls, a central shelf with side storage, an additional 115-volt electric outlet, and a total of six passenger and three pilot ports. Deliveries began in June with the first nine shipped in that month, according to the General Aviation Manufacturers Association. But underscoring the importance of U.S. approval, Nicolas Chabbert, senior v-p of the OEM's airplane business unit, said during EBACE that the majority of orders to that point had come from customers in North America.   · Being able to use biometric identification to speed up travel processes · To be able to track their baggage · Maximum wait times of 10 minutes for baggage collection and immigration / customs · Access to Wi-Fi on board at 34,000ft More Control  . Biometric technology to speed up airport processes Time is of the essence for passengers Onboard Wi-Fi Passengers want onboard Wi-Fi. Some 53% of surveyed passengers found Wi-Fi important to have. The importance is the highest in Africa (71%), Latin America (68%) and the Middle East (67%) and the lowest in Europe (44%) and North America (49%). Passenger pain points  To improve the connection experience, the top three desires from travellers are not having to go through security at the transfer airport (60%), not having to pick up and reclaim their bag at the transfer airport (59%) and not having to pass immigration at the transfer airport (55%).  Adel Al Redha said, "This day has been in the making for some time, and the Emirates A380's grand debut in Cairo is the culmination of a lot of planning and hard work. We mark a new chapter in our long-relationship with Egypt by bringing our flagship aircraft to the country. We hope to play a part in Egypt's success by supporting trade and tourism, and bringing the country closer to the world. We would like to thank the Egyptian government, the Ministry of Transport and the government authorities who have been invaluable in making Emirates' first A380 service a tremendous success. We look forward to operating the A380 on a scheduled basis to and from Cairo." The Emirates A380 operating to Cairo is set in a three-class configuration, and will have 426 seats in Economy Class on the lower deck, 76 flat-bed Business Class seats and 14 luxurious First Class Suites. First Class passengers can relax and revitalize in one of the two A380 Shower Spas, and First and Business Class passengers are welcome in the Onboard Lounge to enjoy an extensive range of beverages and delicacies. Passengers in all classes can enjoy complimentary meals and beverages, Wi-Fi, hospitality and service from multi-national cabin crew and Emirates' award winning 'ice' with up to 4,500 channels of movies, TV programs, music and podcasts. Premium customers, and Platinum and Gold Skywards members can additionally enjoy the dedicated Emirates Lounge in Cairo airport, which opened in 2018. Popular destinations on the Emirates network for Egyptian travellers include cities in the Asia, the Americas and Australia such as Beijing, Bangkok, Hong Kong, Sydney, Shanghai, New Delhi, Mumbai, New York and Washington DC. Emirates started operations to Cairo in April 1986 with three flights a week and since then, have carried more than 7.3 million passengers to and from Cairo. Operations have steadily grown with increases in both frequency and capacity between Cairo and Dubai to match customer demand. Today, Emirates operates 21 weekly flights between Cairo and Dubai. Earlier this year, Emirates announced it will increase the frequency of flights between Dubai and Cairo, adding four additional flights a week to its existing thrice-daily service, starting 28 October 2019, taking the total number of weekly Emirates flights serving Cairo to 25. Globally, the airline employs more than 2,000 Egyptian nationals in a variety of roles across the Emirates Group, including over 1,000-cabin crew.   This accomplishment demonstrates a level of reliability that exceeds EASA's stringent requirements for single-engine helicopters performing commercial operations. "We believe this milestone is a testament to the R66's outstanding performance and confirms its place as a leader in the helicopter industry," said Kurt Robinson, President of Robinson Helicopter. Certified in October 2010, the first production R66 was delivered the following month. Since then, over 960 R66s have been produced, providing dependable performance to operators all over the world. Not only has the R66 proven itself on a daily basis but it has also risen to the unique challenges of flying to the North Pole and circumnavigating the globe multiple times. When asked about the R66, Robinson dealer Les Gillespie of Gardner Aviation (Peachtree City, Georgia) said, "The R66 has quickly become our dealership's number one selling helicopter. Our customers compliments its power, space, and stylish looks. With all the available options like SAS Autopilot, extended range fuel tanks, and glass touchscreen panels, the R66 can be configured to meet the needs of any pilot or helicopter flight department." Robinson Helicopter Company, along with its international dealer network, is expanding its global presence by providing high quality, reliable helicopters throughout the world.   To-date, ATR has already recorded 20 commitments from operators and lessors for this variant, including Elix Aviation Capital (10 aircraft) and Air Tahiti (two aircraft) which were announced at this year's Paris Air Show. The certification of the ATR 42-600S is expected for the second half of 2022, with the first delivery expected immediately after. Compared to a standard ATR 42, the 42-600S will have a larger rudder for increased control of the aircraft at lower speed. It will be able to symmetrically deploy its spoilers to improve braking efficiency on landing, and will come with an autobrake system, to ensure that the full braking power occurs immediately upon landing. Adding the ATR 42-600S to the family paves the way for the company's future. With this new version, ATR forecasts to expand its addressable market by 25%. Close to 500 airports across the globe have a runway comprised between 800-1,000m and could welcome the ATR 42-600S. This is clear illustration of the company's dedication in helping more people and remote communities' benefit from being part of a connected world, in a sustainable way.   USA, Denver: A British Airways Boeing 747-400 on a flight from London Heathrow to Denver when landing at Denver but burst a tyre on touchdown. The aircraft rolled out without further incident, vacated the runway and stopped on taxiway. Emergency services advised the forward inboard right main tyre had blown and that hydraulic fluid were leaking. The crew shut the engines down, the passengers disembarked via mobile stairs and were bussed to the terminal. USA, Chicago-Midway Airport: A Southwest Airlines Boeing 737-700 with 142 on board reportedly suffered blown tires because of a hydraulic issue on landing at Midway Airport. The aircraft stopped on a taxiway, where all passengers deplaned. USA, Unalaska Airport, Alaska: A Saab 2000 with 42 on board operated by Peninsula Airways on a domestic scheduled suffered serios damaged when it experienced a runway excursion after landing at Unalaska Airport Dutch Harbour, Alaska. There were no reported "major" injures to the occupants onboard. USA, Union County, New Salem: A Bell 206 impacted powerlines and heavily wooded terrain during an aerial application flight in Union County, New Salem, North Carolina. The helicopter was destroyed and the sole pilot onboard sustained fatal injuries. Bahamas, Atlantic Ocean offshore New Providence: The Pilots of a Douglas DC3C-S1C3G operated by Atlantic Air Cargo Inc ditched into the waters of the Atlantic Ocean while on approach to Lynden Pindling International Airport Nassau, Bahamas. The airplane submerged, having sustained yet to be determined damage, and the two pilots onboard were not injured during the incident.    Photo © Mztourist / commons.wikimedia.org Maurice Flanagan, who previously worked at British Airways, Gulf Air, and BOAC and at the time was overseeing Dnata, was appointed chief executive officer of the new airline. By the early 1990s, Emirates was among the world's fastest growing airlines; revenue increased approximately US$100 million each year, approaching US$500 million in the year 1993. The airline carried 1.6 million passengers and 68,000 tons of cargo in the same year. With the onset of the Gulf War, business increased for Emirates as the war kept other airlines out of the area; it was the only airline to continue flying in the last ten days of the war. Dubai International Airport's Terminal 3 was built exclusively for the use of Emirates at a cost of $4.5 billion and officially opened 14 October 2008. Terminal 3 is the second largest building in the world by floor space, with over 1,713,000 m2 (423 acres) of space. It is second only to the Boeing Everett Factory. The terminal has annual capacity of 43 million passengers.  |

|

|

|

Copyright © Pilot's Post PTY Ltd

The information, views and opinions by the authors contributing to Pilot's Post are not necessarily those of the editor or other writers at Pilot's Post.